During the HVAC industry, performance, precision, and productiveness are every thing. A person Resource which is quickly reworking how ductwork manufacturing is taken care of would be the insulation reducing equipment. Intended to streamline the fabrication procedure, the insulation chopping device is not merely a luxurious—it’s quickly getting a necessity for manufacturers in search of to stay aggressive. Allow’s take a look at how this technological innovation can revolutionize your operations.

The Purpose of an Insulation Chopping Device in Ductwork Fabrication

The insulation cutting device automates the process of slicing insulation supplies for HVAC duct units. As opposed to depending on guide methods which might be slow and mistake-prone, firms can use an insulation cutting device to provide specific cuts promptly and regularly. This equipment ensures that each piece of insulation fits correctly, decreasing squander and rework even though improving good quality.

Why Handbook Reducing Now not Operates

Common insulation reducing depends on experienced labor and handheld instruments. This approach is time-consuming and sometimes leads to inconsistent final results. Personnel may become fatigued, and measurements can certainly be misread. The insulation slicing equipment removes these difficulties by providing laser-precise cutting driven by pre-programmed layouts. Regardless of whether you’re manufacturing just one duct or hundreds, the insulation slicing equipment gives reliable outcomes whenever.

Vital Advantages of Working with an Insulation Cutting Device

Precision and Precision

An insulation cutting device takes advantage of digital controls to chop with pinpoint precision. No extra uneven edges or misaligned pieces—just best cuts that in good shape duct panels seamlessly.

Improved Generation Speed

With the insulation slicing machine, what when took several hours can now be done in minutes. Large-pace chopping functions let your workforce to fulfill far more orders in fewer time.

Substance Price savings

Manual approaches may lead to excessive waste resulting from inaccurate cuts. An insulation cutting equipment optimizes each sheet of material, reducing scrap and preserving on costs.

Lowered Labor Charges

Automating your insulation chopping tasks with the insulation slicing equipment decreases reliance on manual labor, enabling staff to deal with other value-additional duties in the output line.

Enhanced Security

Insulation slicing can require sharp blades and repetitive motions, both of those of which carry injuries pitfalls. An insulation chopping equipment minimizes human contact with hazardous equipment, advertising and marketing a safer workspace.

How the Insulation Chopping Machine Improves Workflow

Integration is vital in almost any generation line. Fashionable insulation cutting machines can easily be linked to CAD software package, rendering it simple to import style specs. After the requirements are loaded, the insulation slicing equipment does The remainder—cutting with Intense accuracy, labeling elements if essential, and making ready them for assembly. This seamless workflow radically reduces delays and improves General manufacturing effectiveness.

Customization and suppleness

Unique duct devices involve differing kinds of insulation—rubber, fiberglass, or polyethylene. A high-high quality insulation reducing device supports several content sorts and thicknesses. Regardless click here to find out more if you are managing adaptable products or rigid panels, the insulation chopping device adapts to your requirements with no compromising functionality.

Very long-Time period ROI of Buying an Insulation Chopping Equipment

Though the upfront financial investment within an insulation chopping equipment may appear sizeable, the long-term returns are undeniable. Reduced labor costs, minimized waste, faster project turnarounds, and improved client satisfaction all contribute to the good return on investment. Providers that undertake an insulation chopping equipment generally see operational expenditures fall appreciably in the 1st 12 months.

Ultimate Feelings

For HVAC companies trying to modernize their ductwork fabrication method, the insulation reducing machine is really a game-changing Alternative. It provides velocity, precision, Charge personal savings, and basic safety for the manufacturing floor. As demand for top-performance duct devices grows, acquiring an insulation slicing device guarantees you stay ahead of your Levels of competition. Don’t wait around—now's time to improve your workshop and experience the entire ability of the insulation reducing machine.

Alicia Silverstone Then & Now!

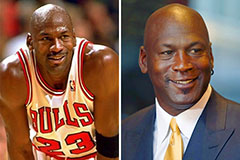

Alicia Silverstone Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now!